How to Get Rid of Laser Cutting Acrylic Smell

Have you ever done some laser cutting with acrylic sheets and been overwhelmed by the unpleasant smell? The laser cutting acrylic smell can linger for hours, or even days.

The unpleasant acrylic burning smell comes from chemicals released when the laser beam hits the material. It’s normal but not the kind of smell you want hanging around. The good news is there are some ways to get the odor out of your workshop easily.

Read on to learn various aspects of the fumes from laser cutting acrylic and some tips on how to get rid of that odor.

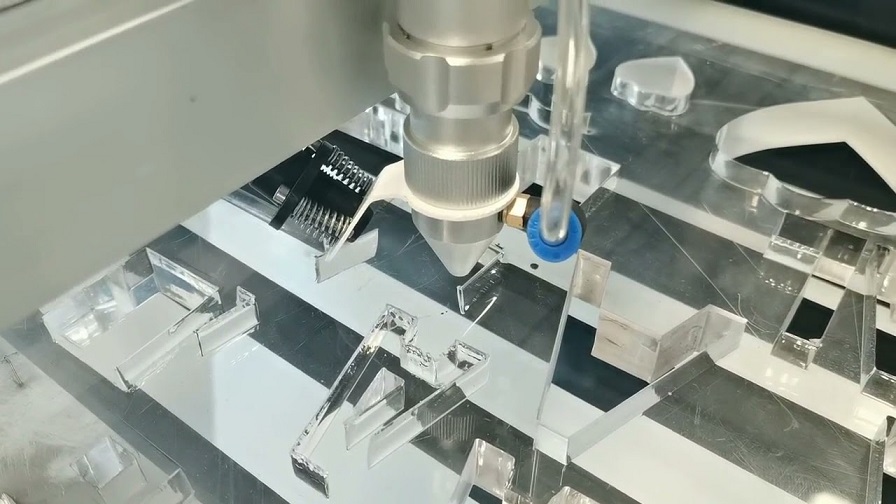

How Does Laser Cutting Acrylic Work?

Laser cutters use a focused laser beam to cut and engrave designs into acrylic sheets. It vaporizes the acrylic along the pattern set in the design file to turn it into the desired shapes and parts. It can also engrave designs by vaporizing only a thin surface layer.

CO2 laser cutting machines are the most common for cutting acrylic. They have a CO2-filled glass tube, which is ionized by using an electric field. The electric current excites the gas molecules to release photons of a specific wavelength.

The tube has mirrors inside that bounce these photons back and forth to build up intensity. Eventually, one mirror lets the concentrated light pass through to the cutting head. What happens then are:

- A focusing lens in the cutting head concentrates the laser beam to a very fine point.

- This high-intensity point melts and vaporizes the acrylic along the pattern.

- An air blast blows away any melted acrylic from the cut line.

Instead of cutting all the way through at once, lasers often make multiple slow passes. This prevents heat damage and yields cleaner, more precise cuts compared to a single fast cut. The precision of laser cutting allows acrylic to be carved into complex shapes and parts.

What are the Fumes from Laser Cutting?

Laser cutting creates fumes that come from the material being cut. As the laser heats up and melts the material, it releases smoke and tiny particles.

Metal fumes contain particles (less than 5-microns in diameter) of that metal. Plastic and wood fumes are more complicated mixtures since they contain gasses from how the laser breaks them down.

It’s important to know what’s in the fumes because some particles or gasses may not be safe to breathe without protection.

a. Acrylic

Fumes from acrylic sheet laser cutting consist primarily of volatile organic compounds (VOCs). Cutting colored acrylic will release more fumes than that of transparent ones. These fumes are low-toxic but can still irritate the respiratory system and eyes.

b. Metal

The fumes from cutting metals consist of metal vapor, metal oxide particles, and potentially hazardous heavy metal compounds, depending on the type of metal you are cutting. For example, stainless steel cutting can release chromium, while aluminum produces aluminum oxide particles.

c. Wood

Wood is a common laser cut material and the fume particles depend on the type of wood you are cutting. Cutting wood releases organic compounds, including aldehydes.

d. Rubber

Rubber laser cutting fumes are primarily composed of sulfur dioxide (SO2) and other organic compounds. Though typically low in toxicity, you should not breathe into it.

Do the Fumes from Laser Cutting Acrylic Smell?

When a laser beam cuts through acrylic, it breaks the plastic down into its basic chemicals. This process makes gas fumes, which usually have smells.

Thicker varieties, like cast acrylic, don’t smell as bad but it’s still not a pleasant one. The clear or colored mirrored acrylics that are pressed together, such as extruded acrylic, can make acrid chemical smells that may stick around for a couple days.

The intensity of the smell depends on the type of acrylic you are cutting. Extruded acrylic is best for cutting designs because it produces the cleanest cuts but this one produces the worst smelling fume.

Are the Fumes from Laser Cutting Acrylic Toxic?

The fumes that come from laser cutting acrylic sheets can cause problems if proper safety steps aren’t taken. While they won’t kill you, they aren’t safe to breathe in, at least, not for a long time. They can make you feel sick with headaches or an allergic reaction. Prolonged exposure over time might even cause asthma for some people.

Heating the acrylic with a laser creates small particles that get into the air. Without good ventilation for laser cutting, the smell can linger on the cut pieces and in the air for a while.

Some common health problems you may suffer from by breathing in laser cutting acrylic fumes are:

- Various allergic reactions

- Skin irritation

- Irritation to lungs, nose, and eyes

- Dizziness, nausea, and headaches

- Tightness in the chest

- Asthma (in case of long-term exposure)

To stay safe, it’s important to cut acrylic in a well ventilated space. You should wear a dust mask labeled for non-oil hazards to prevent inhaling the particles. Move leftover scraps and finished projects outside or into the fresh air as soon as cutting is complete. With the right precautions, laser cutting acrylic is no more dangerous than other similar things, like woodworking and metalworking.

How to Remove Laser Cut Acrylic Smell

The laser cutting acrylic fumes can build up indoors if the air isn’t cleaned out. Such an environment is unhealthy for people working there.

Let’s find out some options for managing the fumes and smell from laser cutting acrylic.

1. Use Air Filters

To get rid of the smelly gasses, you’ll need special filters. Since laser cutting releases both small pieces and air pollutants, you will get the best results by using these filters:

A chemical filter with a pre-filter: Since laser cutting acrylic contaminants are 90% gas and 10% particulates, your air filtration system should have a pre-filter to catch the large particles in the fumes. This keeps the main filter from getting clogged too fast.

The chemical filter grabs the actual fumes before they reach you. Because of having activated carbon, these filters can filter gas pollutants, like VOCs. As a result, they are efficient enough to remove laser cut acrylic smell from the air.

Air purifiers with HEPA and carbon filters: Using an air purifier with both a HEPA and carbon filter is a smarter choice than using either filter alone.

HEPA filters are great at catching small particles like dust from a laser cutting machine. But they won’t do much for odors. That’s the job of the carbon filter. Instead of filtering particles, it absorbs smoke, chemicals, and odors using small holes in the carbon. The laser cutting acrylic smell is mostly made up of gasses released during cutting. It can absorb those smelly gasses before they spread all around.

2. Laser Fume Extractors

A laser fume extractor works in a similar way to regular vacuum cleaners. It has a powerful fan that sucks in the air where the laser is cutting. This draws all the fumes and particles into the machine. Multiple filters inside then work to clean the air before pumping it back out.

For acrylic smells, carbon filters are very effective. Carbon is great at trapping gasses and odors on its internal surface. As the air passes through, the smelly compounds stick to the carbon instead of lingering in the workspace. There are other filters in the extrator to trap larger plastic particles.

By the end of the filtration process, the extracted air should be fresh and odor-free.

3. Low-Cost DIY Solutions

If you’re using laser cutting at your home workshop, you may not want to spend much to set up a big extractor machine. In that case, there are simple DIY solutions:

Use an oven hood. A normal oven hood filter usually traps grease, not gasses. But you can make it work by adding special charcoal inserts. Since charcoal absorbs the laser cutting fumes, it will keep your place odor-free.

Install bathroom ventilation fans. You’ll need a couple high-powered fans. Make sure they have a high cubic feet per minute (CFM) rating to blow lots of air. Attach each one to a dryer vent hose, which helps carry smells outside. Then, put filters in between. One filter traps small particles from the cut materials and another absorbs gasses, like VOCs. Use wood cases to hold the filters over the hoses.

Depending on your project size and whether you need it for commercial purposes or home use, choose a filtration system from these suggested ones to keep your workshop free of laser cutting acrylic smell.

Conclusion

With the right tools and techniques, getting rid of the lingering laser cutting acrylic smell is manageable. Special filters designed to trap smoke, chemicals, and odors work best for this purpose. Even inexpensive hacks, like installing exhaust fans or an oven hood, can make a difference. The most important thing for a fresh-smelling workplace is to have proper ventilation.

Need precision laser cutting materials? Zintilon offers high-quality fabrication with fast turnaround times. Get a quote for an online laser cutting service.